If you’ve ever found yourself asking, “Why is my caulk gun not working?”, you’re not alone. From stuck plungers and dripping nozzles to uneven beads, these issues can turn a simple job into a frustrating one. But here’s the thing — most caulking problems don’t come from user error; they come from the wrong tools.

That’s why at Newborn, we design products that take the hassle out of caulking altogether. You’ll get a professional-grade system built for smooth performance, strong adhesion, and long-lasting results every time. Simply put — Newborn has it all when it comes to caulking done right.

1. The Rod Isn’t Moving Forward

Common cause: The rod might be bent, jammed, or filled with dried caulk.

Fix: Press the thumb release (if applicable) and pull the rod all the way back. Clean any hardened sealant in the cradle, make sure the tube isn’t clogged, and lightly oil the rod for smooth motion. If the rod is bent, straighten it by gently applying pressure with your hands or pressing it against a flat, solid surface. You only need slight, even pressure to bring it back into alignment — avoid forcing it too far in either direction.

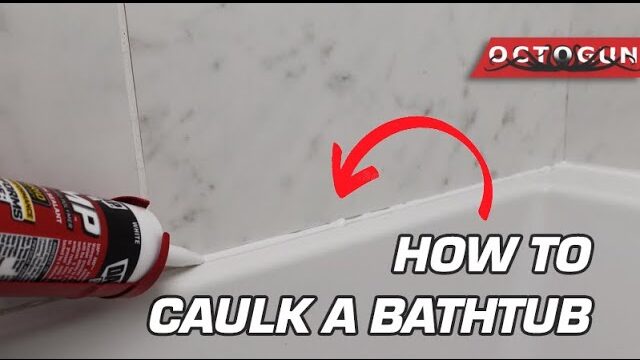

Newborn solution: Not all caulk guns are created equally — cheaper guns often bend, jam, or wear out quickly. The Octogun 208D is built to last, with durable, precision-engineered components that resist the common issues found in lower-grade tools. Its drip-free mechanism keeps the rod cleaner, and the 360° revolving barrel helps prevent the awkward angles that cause rods to bend in the first place. The result: smoother performance and a gun that holds up over time.

Octogun 208D – Integrated Tooling Square

2. The Rod Won’t Pull Back

Common cause: The user isn’t holding the thumb release (if the gun has one), or they’re trying to pull the rod back at an awkward angle.

Fix: Before pulling the rod back, angle the gun downward at about 45°. If your model has a thumb release (the small tab above the trigger), press it down. Hold only the back handle—if you grip anywhere else, you’ll engage the friction plate, which stops the rod from moving in either direction.

Newborn solution: The Newborn 250 uses a smooth rod and a precision-engineered drive system that resets effortlessly. Its advanced design ensures consistent pull-back performance with less drag, eliminating the sticking or resistance common in lower-grade guns. Built with durable, high-quality components, it’s made to withstand daily jobsite use and deliver a reliable, predictable pull every time.

With its smooth rod, reinforced frame, and long-lasting construction, the Newborn 250 provides a quicker, cleaner reset that keeps your work flowing. It’s an ideal choice for contractors who want a gun that performs exactly as it should—smooth, steady, and built to last.

3. The Caulk Won’t Come Out

Common cause: The seal inside the tube isn’t punctured, or the nozzle is clogged.

Fix: Make sure the inner foil seal is fully pierced and cut the nozzle cleanly at a 45° angle. Check that the plunger is aligned and the tube isn’t deformed.

Newborn solution: The Octogun 208D includes a built-in spout cutter and seal puncture tool — no extra tools needed. And when paired with Octogun Silicone Sealant, you get a next-generation formula that flows smoothly and evenly through the nozzle.

Unlike traditional acetoxy silicones, Octogun Silicone is a neutral-cure alkoxy formula that produces little to no odor, won’t corrode metals, and bonds powerfully to glass, plastics, acrylic, masonry, and natural stone. It’s 100% waterproof, flexible, and resistant to cracking, shrinking, and yellowing — making it ideal for kitchens, bathrooms, windows, and outdoor projects.

Octogun Silicone Sealant for Superior Adhesion

Octogun 208D – Integrated Tooling Square

4. The Caulk Keeps Dripping After You Release the Trigger

Common cause: Your gun doesn’t automatically release pressure after use.

Fix: Choose a drip-free caulk gun. The Octogun 208D’s drip-free mechanism retracts pressure automatically, so your line stays clean without unwanted drips.

Plus, it features an integrated 4-sided tooling square and caulk removal tool, letting you prep, smooth, and finish without switching tools.

Octogun 208D – Integrated Tooling Square

5. The Trigger Feels Stiff or Stuck

Common cause: Dried sealant or rust buildup in the trigger assembly.

Fix: Soak the front end of your gun in warm, soapy water (avoid submerging the handle), scrub away residue, and apply a small amount of lubricant to keep it moving freely.

Newborn solution: The Octogun 930-GTD is designed to minimize these issues from the start. Its patented Gator Trigger™ Comfort Grip provides an ergonomic, fatigue-reducing feel during long use, while the lightweight frame keeps handling easy. Plus, the built-in ladder hook and integrated caulk plug help keep your setup organized and your tubes sealed and fresh between uses.

Octogun 930-GTD – Drip-Free Hex Rod Cradle

How to Keep Your Caulk Gun Working Like New

To get the longest life out of your tools, follow these simple care tips:

- Clean after each use: Wipe away excess caulk before it hardens.

- Store upright: Prevents sealant from leaking into trigger components.

- Use high-quality sealant: Octogun Silicone resists clogging, stays smooth, and keeps your gun clean inside.

- Lubricate occasionally: Keeps the plunger and trigger mechanism moving freely.

Final Thoughts: Newborn Has It All

When a caulk gun stops working, it’s usually a sign that you need tools built to perform — not just get by. A well-designed caulking tool should deliver smooth, controlled application, reduce mess with reliable pressure release, and include features that make the job easier from the first squeeze to the final cleanup. Pairing a quality gun with a high-performance sealant ensures better adhesion, flexibility, and long-term durability across a wide range of surfaces.

From start to finish, Newborn has the right tools and materials makes every job faster, cleaner, and more consistent — giving you results you can rely on.