Whether you’re a homeowner looking to retile the bathroom or a seasoned contractor getting ready to fill in concrete joints, selecting the right caulking or sealant gun can feel like a daunting task. With so many types of adhesives, sealants, and dispensing tools available, it’s easy to get caught up in brand names, price points, and flashy features. But amidst all these considerations, there’s one key factor that often goes overlooked: the trust ratio, which is essential for effective application. Understanding the trust ratio can greatly enhance your application process and ensure optimal results.

Now, you might be thinking, “Trust ratio… what exactly is that?” Don’t worry; it’s not as complicated as it sounds. In fact, understanding trust ratio can save you time, money, and a lot of unnecessary hand fatigue. Think of the trust ratio as the muscle behind your gun—an indication of how much force the tool applies to extrude the material with each squeeze of the trigger.

In practical terms, the trust ratio can make or break your project. A higher trust ratio typically means a more efficient application, allowing you to work smarter, not harder. It’s crucial to keep the trust ratio in mind when selecting your tools.

By the time you finish reading this, you’ll know not only what trust ratio is, but also why it matters, how to choose the right one for your project, and how it can make your next job a whole lot easier. Let’s dive right in and explore the importance of trust ratio in your caulking projects.

For many professionals, the trust ratio is a critical factor in selecting the right caulk gun. It directly affects the performance and efficiency of your work.

What Is Trust Ratio?

Understanding the trust ratio also helps in selecting the right materials for your projects. By choosing materials that align with your gun’s trust ratio, you can ensure a smoother application.

The importance of the trust ratio cannot be overstated. It can influence the quality of your work and the level of comfort you experience during application.

At its simplest, the trust ratio is a number that tells you how much mechanical advantage the gun’s drive mechanism provides. In other words, it’s the relationship between the pressure you apply on the trigger and the force applied to the material inside the cartridge. If you have a 6:1 trust ratio, that means for every 1 pound (lb) of force you generate by squeezing the trigger, the gun pushes with 6 lbs of force on the cartridge’s plunger.

By paying attention to the trust ratio, you can make a more informed decision about your tools, ensuring the best fit for your specific needs.

This is crucial because not all materials are created equal. Some sealants and adhesives are thin and flow easily with minimal effort, while others are thicker and require more force. By understanding thrust ratio, you can ensure that you have the muscle you need to move your material at a comfortable pace.

How Thrust Ratio Is Measured

The thrust ratio is determined by the gun’s internal gearing and lever systems. Manufacturers design the rod, handle, and internal components to multiply your input force. By adjusting factors like gear configurations and handle pivot points, they can produce caulk guns ranging from low-thrust models (3:1) to high-thrust powerhouses (34:1).

Just like a lever helps you lift heavy objects with less effort, a caulk gun’s thrust ratio helps you extrude thick materials without straining your hands. Different guns provide different mechanical advantages, allowing you to match the tool to the task.

Why Thrust Ratio Matters

Thin vs. Thick Materials

The main reason thrust ratio is important is that not all adhesives and sealants are the same. Some, like acrylics and silicones, are thin and flow easily through the nozzle. Others, such as polyurethanes, firestop materials, and epoxies, are much thicker. If you try to dispense a thick material with a low-thrust gun, you’ll struggle, potentially leading to hand fatigue, uneven lines, and frustration.

Comfort and Efficiency

Choosing the right thrust ratio means you won’t be fighting against the material. Instead, you’ll be working with the gun, applying the perfect amount of force for a clean, professional result. In turn, this improves efficiency, reduces strain, and helps ensure a higher quality finish.

Ultimately, the trust ratio is a fundamental aspect of any caulk gun, and understanding it can significantly enhance your project outcomes.

Balancing Force and Material Flow

There’s a trade-off to consider: the higher the thrust ratio, the stronger the drive mechanism and the easier it is to extrude thick material. However, a higher thrust ratio often means you’ll dispense less material per trigger pull. Think of it like shifting gears on a bicycle. A low gear makes pedaling easier but covers less distance with each rotation.

In caulking terms, a high-thrust gun lets you push thick materials effortlessly but might require multiple pulls to lay a continuous bead. Conversely, a lower-thrust gun dispenses more material per pull but requires more hand strength to push thicker products.

Choosing the Right Thrust Ratio for Your Project

Choosing the right trust ratio is about more than just numbers—it’s about achieving results that meet both your standards and your client’s expectations.

For Light Materials (Acrylics, Silicone, Latex)

If you’re working with thin, easy-flow sealants like acrylic or silicone, you don’t need a ton of force. Guns in the 3:1 to 6:1 range are ideal here. You’ll appreciate the smooth, steady flow of material and the ability to work quickly, laying down long beads without breaking a sweat.

For Medium-Viscosity Sealants (Polyurethanes, Some Butyls)

If you’re dealing with more substantial materials—like construction adhesives or polyurethane-based sealants—you may want something in the 10:1 to 12:1 range. This provides enough muscle to handle thicker substances without forcing you to grip the handle with all your might.

For Heavy-Duty Projects (Epoxies, Firestop, Highly Viscous Adhesives)

When tackling thick, resistant materials, higher thrust ratios (18:1, 24:1, or even 34:1) are the way to go. These guns make pushing out stubborn materials a breeze, ensuring a consistent, professional-quality bead every time. The added mechanical advantage also reduces hand fatigue and allows for more precise control.

Considering Environmental and Project Conditions

Temperature Effects

Temperature plays a significant role in material viscosity. A sealant that flows freely at room temperature might thicken in colder conditions. If you’re working outdoors in a cooler climate, a higher thrust ratio can help maintain a smooth, even flow despite the change in consistency.

Project Size and Complexity

For small home projects, you might not mind using a lower-thrust gun, especially if the material is thin. But if you’re a professional working on large commercial sites with dozens of joints, a higher-thrust gun improves efficiency, reduces fatigue, and keeps your workflow steady.

User Comfort

Don’t overlook personal comfort. If you have wrist issues or anticipate long hours on the job, a higher thrust ratio can help you work comfortably, reducing the risk of strain and injury.

Real-World Scenarios

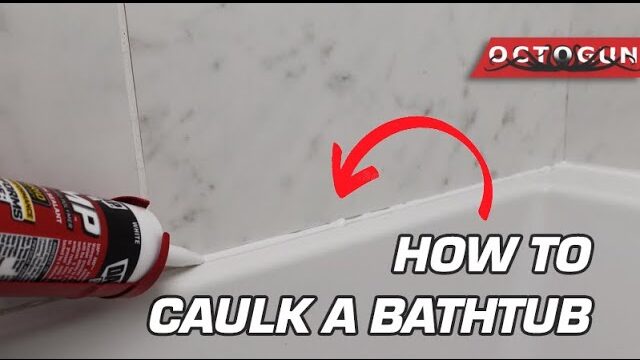

Retiling a Bathroom

Imagine you’re sealing around your new bathroom tiles using silicone caulk. Silicone is thin and flows easily, so a 6:1 thrust ratio gun will be sufficient. Each trigger pull releases a nice, continuous bead, letting you move quickly and finish the job without sore hands.

Filling Concrete Joints

In conclusion, the trust ratio should guide you as you navigate the wide array of tools available. It’s your key to efficiency and effectiveness.

Now consider sealing the expansion joints in a concrete driveway with a polyurethane-based product. This material is thicker and more resistant to flow. If you pick a low-thrust gun (3:1), you’ll struggle. But move up to a 12:1 or 18:1 model, and you’ll find the work significantly easier, reducing fatigue and improving the consistency of your line.

Applying Epoxy for Structural Repairs

Epoxies are notoriously thick and can be challenging to dispense. A 34:1 thrust ratio gun gives you the extra force you need. Suddenly, epoxy flows more readily, allowing for careful, controlled application without wearing out your grip.

Understanding the Trade-Offs

A higher thrust ratio gives you more power but less material per trigger pull. While that might slow you down on large-scale jobs, it can be beneficial when precision counts. If you’re applying an expensive, specialty sealant, you’ll value the greater control that comes with a higher thrust ratio.

On the other hand, if speed and covering large areas matter more, a lower thrust ratio might let you work faster with lighter materials, dispensing more product each time you squeeze the trigger.

Quality and Durability Considerations

High-thrust guns are often built with more robust components to handle the added stress. They may feature sturdier frames, stronger rods, and higher-quality mechanisms. While this can mean a bigger initial investment, it often pays off in durability and reliability, especially for professionals who use their tools frequently.

Beyond Thrust Ratio: Other Features to Consider

Ergonomics

A comfortable grip and ergonomic handle design can make a huge difference, especially if you’ll be working for extended periods. Some guns also offer rotating frames, allowing you to maintain a consistent bead angle around corners.

Dripless Design

A dripless caulk gun helps prevent material from oozing out after you release the trigger. This reduces mess, waste, and cleanup time.

Cartridge Size Compatibility

Make sure the gun you choose can handle the sizes and types of cartridges you plan to use. Some guns accommodate various cartridge styles, including sausage packs, giving you flexibility for different projects.

Adapting to the Job at Hand

If you’re a homeowner who only occasionally takes on small fixes, a single, moderate-thrust gun might be all you need. But if you’re a professional or a serious DIY enthusiast, consider owning multiple guns, each with a different thrust ratio. This ensures you always have the perfect tool for any type of job or material.

Determining Your Ideal Thrust Ratio

Start by considering the material you use most:

- Mostly Thin Caulks: 6:1 to 10:1

- Mid-Viscosity Products: 12:1 to 18:1

- Thick, Stubborn Materials: 18:1 and above

If possible, try out different guns to see how they feel in your hand. A quick test at the hardware store can help you find a ratio that feels comfortable and efficient.

Maintaining Your Caulk Gun for Peak Performance

Cleaning and Lubrication

Always clean your gun after use, removing excess sealant before it dries. Lubricating the rod and other moving parts ensures smooth operation and helps maintain the thrust ratio performance over time.

Checking for Wear

Over time, parts may wear out. Keep an eye on the rod, gears, and springs. Replacing worn components promptly will prevent bigger problems down the line.

Referring to sources that emphasize the importance of the trust ratio can only enhance your understanding and application.

Environmental and Economic Benefits

When you choose the correct thrust ratio, you’re more likely to apply just the right amount of material without waste. This efficiency translates to cost savings and reduced environmental impact. Over the lifespan of multiple projects, using the right gun for the job can add up to significant benefits for your wallet and the planet.

Industry Trends and Innovations

So, as you consider your next project, remember to evaluate the trust ratio of your caulk gun—it’s essential for optimal performance.

With the right trust ratio, you can ensure your work is not only efficient but also of high quality.

Manufacturers are continually improving caulk gun designs, incorporating ergonomic handles, lightweight materials, and advanced gearing systems. Some models even allow you to switch between thrust ratios, offering greater versatility on the job site. Keep an eye on emerging product innovations, as the field is always evolving.

Referring to Reliable Sources

For more detailed information, consider checking out reputable manufacturers and suppliers. Companies like Newborn offer comprehensive guides and charts to help you choose the correct thrust ratio for specific materials. Their websites and customer support can provide valuable insights and recommendations.

Conclusion

Thrust ratio might seem like a small detail, but it can have a big impact on the comfort, efficiency, and quality of your next sealing or adhesive project. Whether you’re handling simple home repairs or tackling complex professional tasks, understanding thrust ratio helps you select the perfect caulk gun for the job.

Think of thrust ratio as the “gearing” of your caulk gun. By choosing the right ratio, you make it easier to extrude thick materials, reduce hand fatigue, and produce cleaner, more consistent beads. Don’t underestimate the value of this often-overlooked factor.

Next time you’re shopping for a caulk gun—online or at the local hardware store—pay close attention to the thrust ratio. Consider what materials you’ll be using, what conditions you’ll be working in, and the level of control you need. With a little extra knowledge, you can make a truly informed choice, ensuring a smoother, more efficient, and more enjoyable project experience.

Happy caulking!